Main configuration and features

1. It adopts stainless steel chain track, frequency conversion adjustment motor, and adjustable operation speed of the equipment, which can meet the cleaning requirements of plastic bottles (glass bottles) with different production volumes and varying degrees of cleanliness.

2. The water tanks are all cleaned with horizontal stainless steel centrifugal water pump circulating spray cleaning, inclined design, with automatic device, unified water inlet, unified sewage discharge; each water tank is equipped with a filter device (the internal filter device is a three-layer filter), which is convenient Clean up dirt at any time; there is also a slide design under the water tank, and all water tanks can be drawn out separately for easy operation and cleaning.

3. The cone-shaped stainless steel nozzle is a three-dimensional four-directional installation structure, which is staggered and distributed, and the cleaning angle is adjustable, which makes multi-directional cleaning more convenient.

4. The guardrail rails on both sides of the bottle washer can be adjusted according to the width of the bottle, and the top spray pipe can be adjusted up and down, which is suitable for cleaning bottles of different heights.

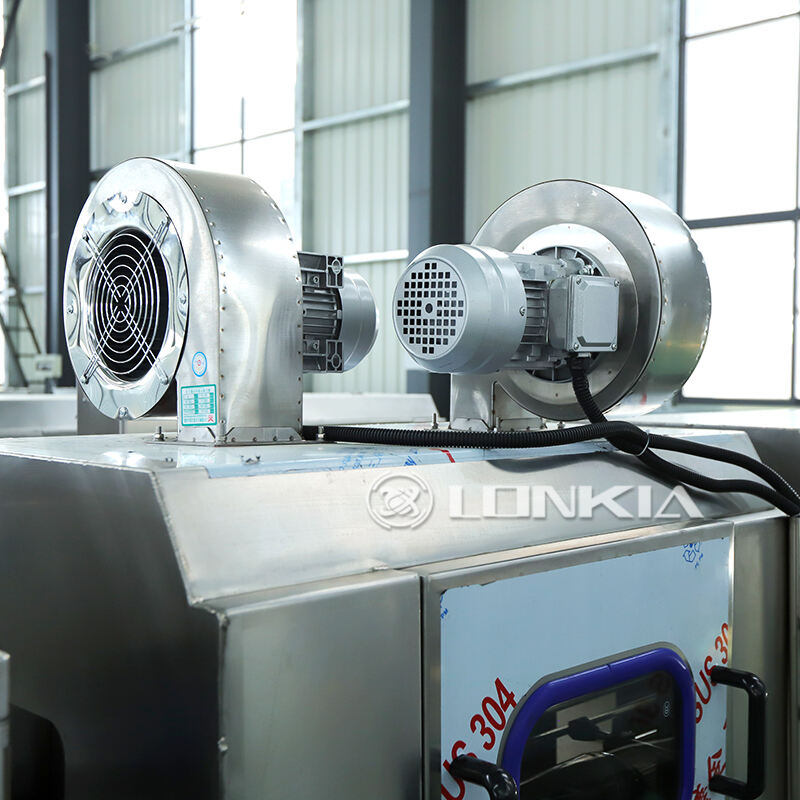

5. Exhaust vent: The moisture generated after the steam is heated is discharged through this port. The three-layer silicone curtain at the end of the bottle prevents water from splashing out and prevents the hot air from spilling and hurting the operator. Each section has three water-retaining curtains. Prevent the water from mixing in the two tanks.

6. There are movable waterproof doors on both sides of the cleaning room, and soft curtains are used to seal the waterproof ends, which is convenient for cleaning and repairing the equipment at any time.

7. Conventional equipment is three-stage cleaning. The first two stages are hot water cleaning. Alkaline water and detergent water can be added to remove oil stains according to product requirements. The third stage is clean water flushing (also can be customized as two-stage or four-stage according to special requirements. Segment cleaning).

8. The conventional cleaning efficiency is 300-1200 pcs/h (specifically determined according to the degree of messiness of the customer's product).

9. Equipped with a stainless steel electrical control box to centrally control all power; electrical appliances are equipped with overload protection and leakage protection; the front and rear ends of the equipment are equipped with emergency stop devices, which can be stopped if necessary.

10. The equipment has the characteristics of low energy consumption, good production and cleaning effect, simple maintenance, easy installation, labor saving, etc., if the customer's special requirements, the surface can be air-dried and dried.